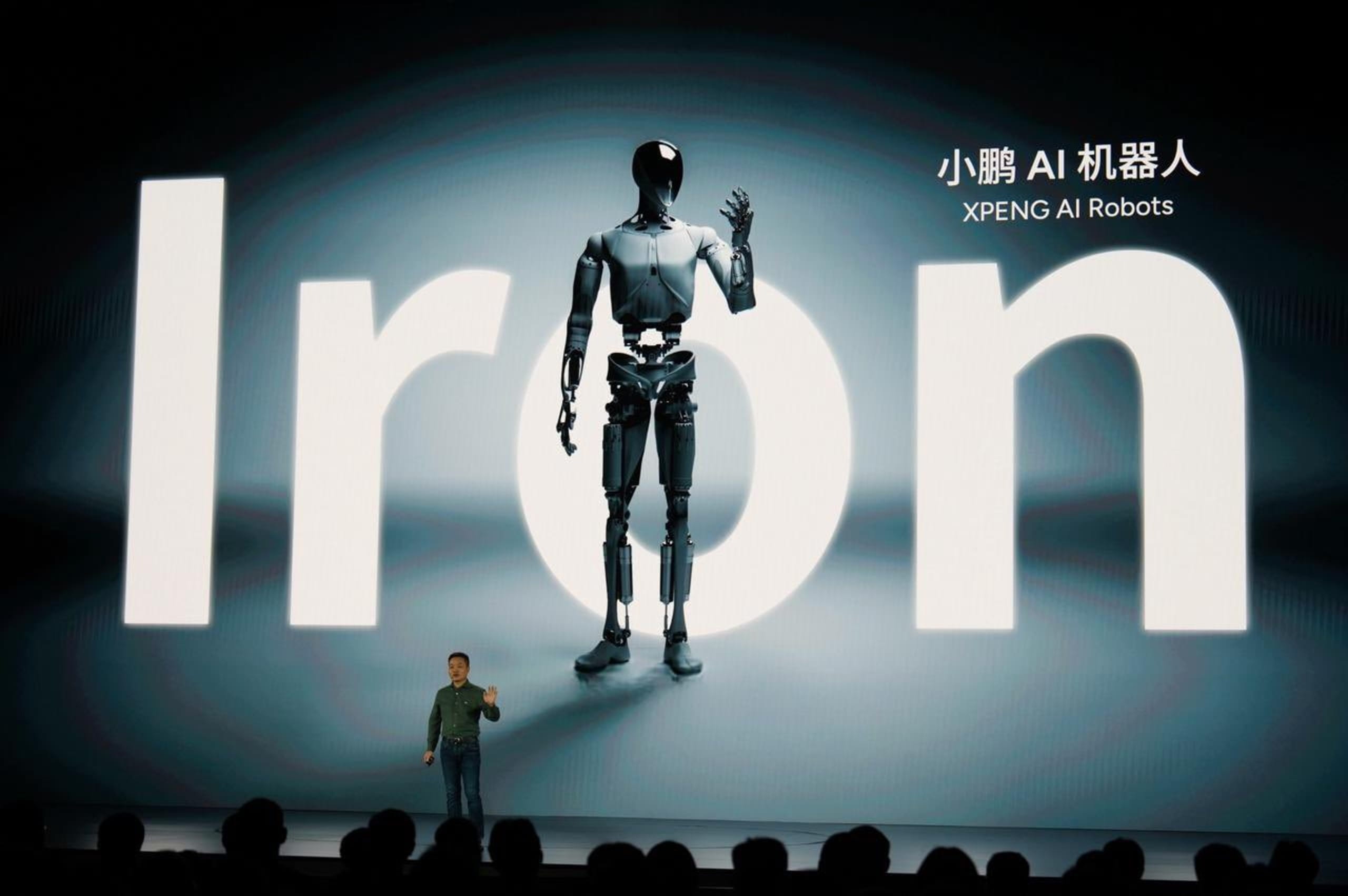

Xpeng just launched their humanoid robot Iron at AI Day, and the specs are seriously impressive! We’re talking about a full-size bipedal system standing 178cm tall and weighing 70 kg—pretty much human-scale, which is awesome for real-world integration.

Neural Architecture Deep-Dive

The brain of this beast is wild – Xpeng built a custom 40-core Turing AI chip that can handle 30 billion parameter models. Machine learning nerds, you’ll appreciate this: they ran 2,791 functional verifications in just 40 days. That’s faster than standard development cycles! The neural nets are getting their training data straight from Xpeng’s autonomous vehicle programs – talk about transfer learning in action.

Joint Control System (Warning: Technical Details Incoming!):

- 60+ articulated joints creating 200 degrees of freedom.

- Each hand rocks 15 degrees of freedom with force feedback.

- Running on the Canghai Platform with a 33x bandwidth boost.

- Vision processing 12x faster than previous gen.

- Level 4 autonomous movement capabilities.

Real Factory Implementation

Iron is already assembling P7+ EVs on Xpeng’s production lines. According to the International Federation of Robotics, this fits into China’s massive 51% surge in industrial robot deployments last year. The robot is using deep learning for object manipulation – we’re talking sub-millimeter grasping accuracy here.

Here’s where it gets controversial – Figure AI’s CEO Brett Adcock called out some interesting similarities: “They copied our entire spine/hips on Figure 01.” But hey, convergent evolution in robotics design is a thing, right?

https://x.com/adcock_brett/status/1854280888328364181

Performance Metrics (Fresh from Zhaoqing Plant)

The Eagle Vision system’s crushing it with object recognition and real-time sensor fusion. They’re using transformer-based models for motion planning – same tech that’s powering their autonomous vehicles. The robot’s currently mastering specific assembly sequences requiring high-precision manipulation.

Market Context for Fellow Data Nerds

The Market size is projected to be $32.5B for industrial robotics by 2028. Iron’s joining some serious competition:

- Tesla Optimus (11 DOF hands)

- Boston Dynamics Atlas (hydraulic systems)

- Figure-02 (advanced locomotion)

- Agility Robotics Digit (spring-mass dynamics)

Similar Posts

Future Development Pipeline

Xpeng’s CEO He Xiaopeng dropped some hints about expanding Iron’s capabilities. They’re working on:

- Enhanced environmental awareness systems

- New safety compliance protocols

- Retail/office environment adaptations

- Advanced human-robot interaction algorithms

Technical Challenges

They’re Tackling: The team at South China University of Technology is optimizing those machine learning models for better dynamic balance control. They’re using cloud-based updates to continuously refine motion planning and object interaction – classic MLOps approach.

https://longportapp.com/en/news/219041635

Neural Processing Stats:

- 40-core processor

- 30B parameter models

- 33x bandwidth improvement

- 12x faster image processing

- Real-time sensor fusion capabilities

For my fellow roboticists – we’re watching China’s automation sector grow at hyper speed. 276,288 industrial robots deployed in 2023 alone! Iron represents their push into advanced humanoid systems, though questions about innovation versus adaptation remain open.

Bottom Line

Whether you’re into neural networks, mechanical design, or industrial automation, Iron’s technical architecture offers some fascinating insights into the future of humanoid robotics. The real test will be seeing how those specs translate to long-term factory performance.

Keep your sensors calibrated, fellow robot enthusiasts! What aspects of Iron’s tech stack interest you most? The neural processing unit? The joint control system? Drop your thoughts in the comments!