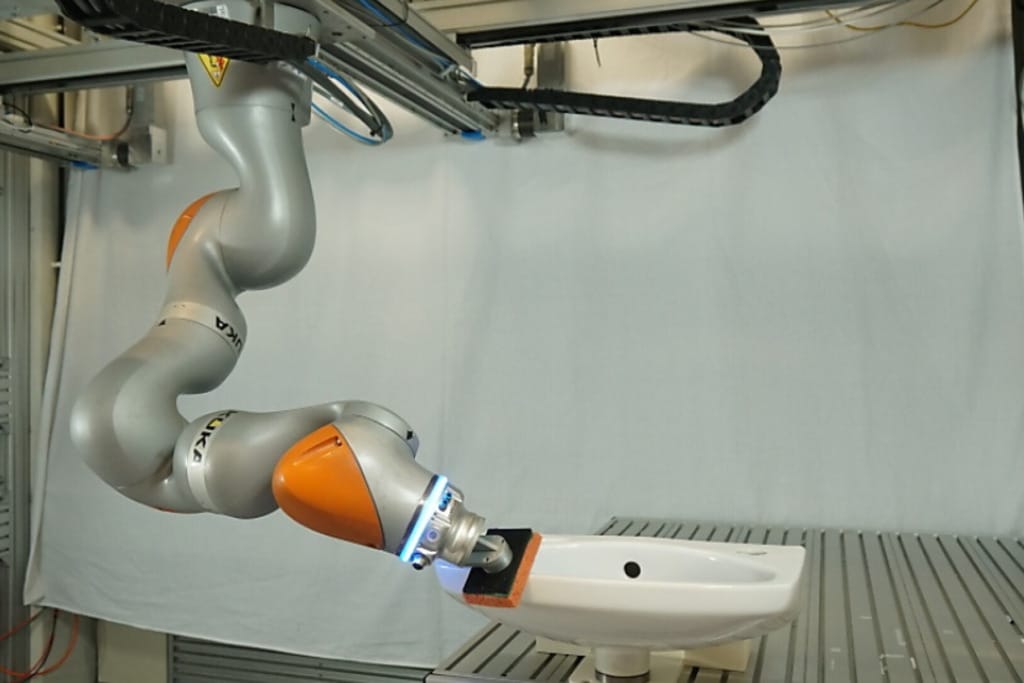

A research team at TU Wien (Vienna University of Technology) has developed a robot system capable of learning how to clean washbasins by observing human demonstrations. The project earned the ‘Best Application Paper Award’ at IROS 2024 in Abu Dhabi, out of more than 3,500 submitted papers.

Technical Implementation

The system centres on a specially developed cleaning tool: a sponge equipped with force sensors and tracking markers. As Professor Andreas Kugi from the Automation and Control Institute at TU Wien explains: “Capturing the geometric shape of a washbasin with cameras is relatively simple. But that’s not the crucial step. It is much more difficult to teach the robot: Which type of movement is required for which part of the surface? How fast should the motion be? What’s the appropriate angle? What’s the right amount of force?”

The learning process in the robot system is based on an innovative data processing strategy developed at TU Wien. Christian Hartl-Nesic, the head of the Industrial Robotics group, explains that their approach involves generating a large amount of data from just a few demonstrations, which is subsequently processed to teach the robot what proper cleaning involves.

The strategy incorporates various established machine learning techniques.

- Statistical processing of measurement data.

- Training a neural network to learn predefined movement elements (“motion primitives”).

- Optimal control of the robot arm for surface cleaning.

Learning Capabilities

PhD student Christoph Unger from the Industrial Robotics group explains that the system is adaptable, noting that the robot learns to adjust the way it holds the sponge depending on the shape of the surface. He adds that the robot also learns to apply different amounts of force when cleaning tightly curved areas compared to flat surfaces.

A key achievement is that after training on just the front edge of a sink, the robot can clean entire sinks and other objects with complex surfaces.

Similar posts

Industrial Applications

The technology extends beyond cleaning to various surface treatment processes:

- Sanding wooden workpieces in joineries.

- Repairing and polishing paint damage in vehicle bodies.

- Welding sheet metal parts in metalworking shops.

Future Development: Federated Learning

Professor Kugi outlines a vision for knowledge sharing between robots: “Let’s imagine many workshops use these self-learning robots to sand or paint surfaces. Then, you could let the robots gain experience individually with local data. Still, all the robots could share the parameters they learned with each other.”

This federated learning approach would:

- Keep specific workpiece data private.

- Share essential basic principles between robots.

- Improve capabilities across all connected systems.

The research demonstrates practical progress in robot learning through human demonstration, with potential applications across various industrial surface treatment tasks.